Custom toll processing expertise for marketplace advantages.

Our innovative fluid bed jet milling services utilize a special autogenous milling technology that incorporates a dynamic air classifier that can be infinitely adjusted to the desired particle size and shape. Our mills include hot gas, ceramic lined, and stainless steel varieties to meet your specialized needs.

During our pre-crushing size reduction process, two metal plates break large chunks of material using compression. The bottom gap between the plates, through which material passes, can be adjusted for the size needed.

Our hammer mills create high-shear and centrifugal forces to reduce an exceptionally wide range of friable and non-friable materials. End products result in coarse fractions down to finer particle sizes regulated by a range of inline screens.

Our high-speed, fine-impact universal mills can dry grind various products from 50 microns to 2 millimeters. Depending on the application and product, the mills can be equipped with four rotating and stationary elements to meet the desired end product fineness.

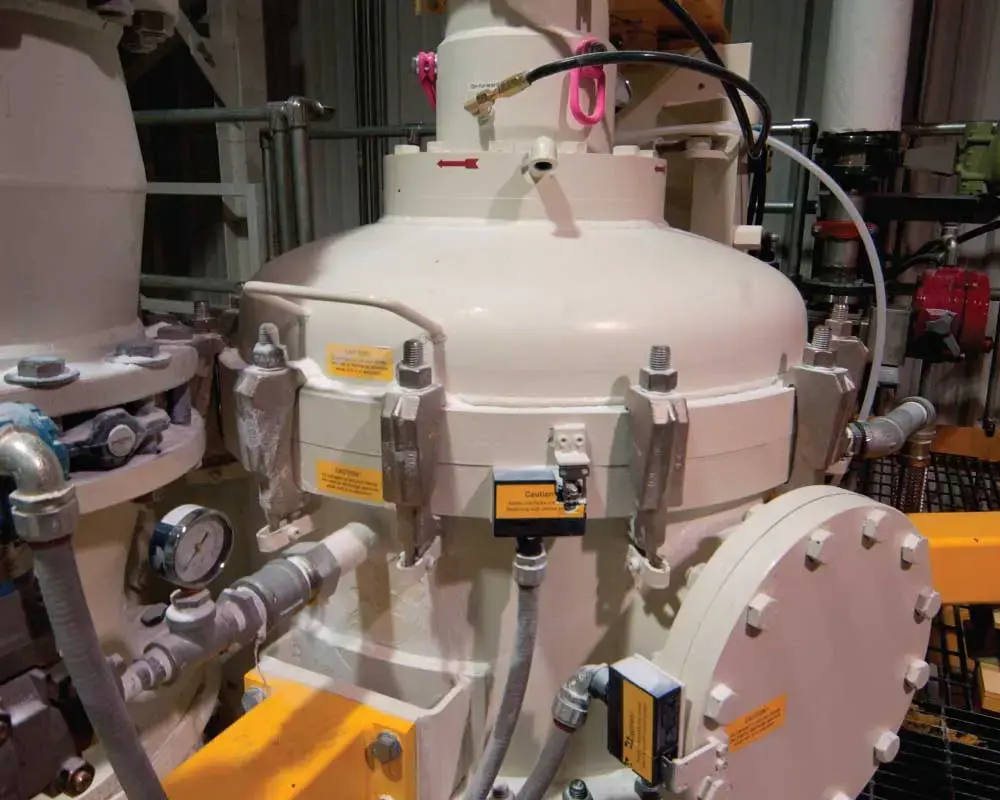

Our coarse system technologies include primary crushing, impacting, drying, roll crushing, utilizing large screen decks to customize several size fractions simultaneously. Our inline, air-swept pulverizing roller mill grinds and classifies where oversized product is recycled for further grinding.

Particles are dispersed in a liquid slurry and media milled to obtain a uniform particle size distribution. The shearing forces (tearing apart), impacting (crushing by outside forces), and attrition (tearing and crushing each other apart) create particle distributions in the nanometer or sub-micron ranges.

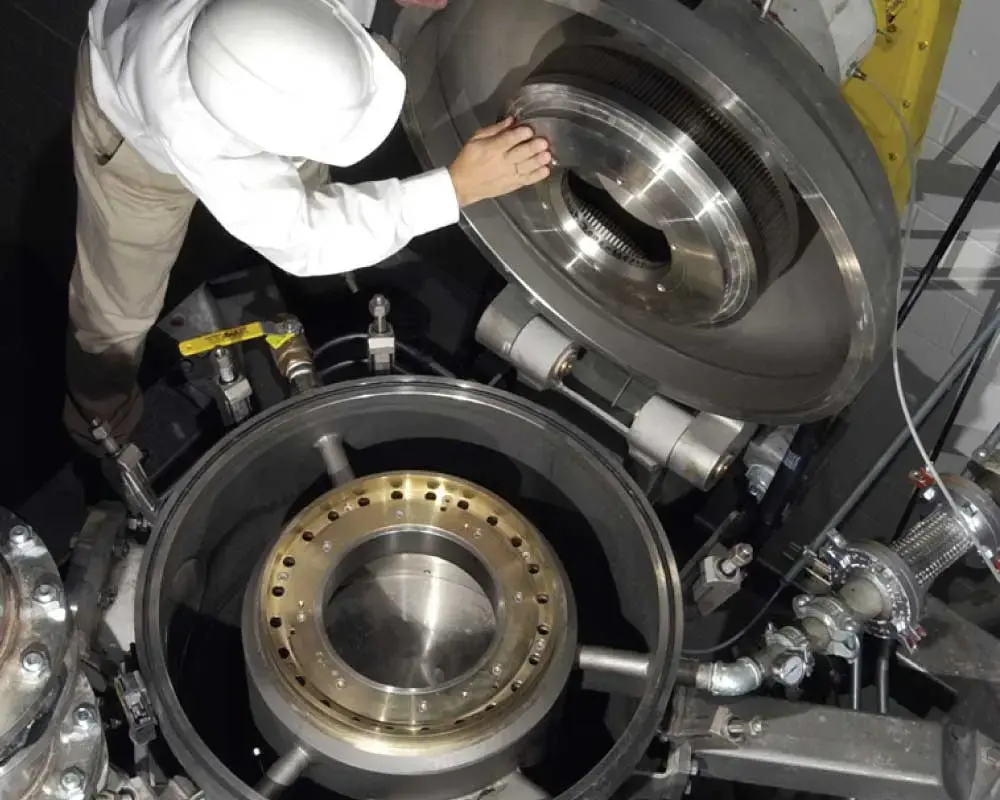

The media in autogenous grinding can be large pieces of material, so this technique is milling by attrition (self-grinding), not by impact. A rotating drum creates a cascading motion that causes breakage into finer particles.

You’ve found a rarity: a technically proficient, passionate, full-service provider of toll processing services that also has a business mindset, focusing our efforts on your bottom line. Using second-to-none particle technology expertise — and your business goals as inspiration — Custom Processing Services uncovers what’s possible for your products today to elevate your future possibility of success.

CUSTOM TOLL PROCESSING

TOLL MANUFACTURING

CONTRACT PROCESSING

CONTRACT MANUFACTURING

TOLLING ...

(JUST ASK OUR CLIENTS)

Lean on us for food-grade and pharmaceutical processing. Our complete capabilities and dedicated, 45,000-square-foot facility meet the rigorous demands of cGMP production.

When you need an extension of your R&D capabilities, let us show you what we’re made of. We go beyond test grinding to offer a variety of feasibility from pilot scale to full scale services as well as experimenting on novel surface treatments and mineral/additive combinations.

Our customers trust us to process and manufacture products that meet their own standards for quality. Integrity in our processes is the basis for that trust. Our quality and process management certifications prove our commitment to quality and ensure every product we touch meets rigorous safety standards. We hold certifications in ISO 9001, FSSC 22000, GMP, Hemp GMP, and PCO Organic. We are also an approved contract manufacturer for Kosher processing via the Orthodox Union.

For more information on any of our certifications, just click the icon below.

Amanda Leisey

R. Preston

Eddie Murray

H. Bergum